PTG IIA Multi-Mode Thickness Gauge

|

|

▶3.5”true color display . Screen Refresh rate of 60 Hz.

▶ Manual or AGC gain, depending on measure mode selected (70 dB gain range).

▶ Linear time dependent gain (TDG). built into each transducer type.

▶ Display view: A-Scan, Large Digits or B-Scan (cross section) display,Numerical modes include: conventional

thickness value mode, difference / reduction rate mode and maximum value mode;

▶Multiple measurement modes: mb-e, E-E and ME-E modes meet the measurement of conventional thick workpieces;

Thin mode realizes the measurement of thin parts;

▶The measurement range is wide, and the unique technology is adopted to realize the measurement of ultra-thin parts,

with a minimum measurement thickness of 0.15mm (steel)

▶ Can measure the thickness with high precision, and the maximum measurement resolution can reach 0.001mm; The

repetition resolution can reach ± 0.002mm;

▶It has the functions of penetrating coating and echo to echo measurement, which is used to measure materials with paint layer and coating on the surface;

▶It supports a variety of probes, including double crystal probe and single crystal probe, and supports up to 20MHz high-frequency probe;

▶ It supports mass storage and can store 100000 thickness values, 500 groups of A-scan waveforms and 500 groups of B-scan waveforms at the same time;

▶ It has a variety of calibration methods, supports one-point calibration, multi-point calibration and manual calibration modes, and can calibrate sound velocity and probe zero position at the same time; It supports v-path correction of double crystal probe.

▶ It supports the conversion of metric millimeter and inch units

▶ Single and Dual element style transducers.

|

|

|

|

|

|

|

|

Applicable Materials

It is suitable for measuring the thickness of metals (such as steel, cast iron, aluminum, copper, etc.), plastics, ceramics, glass, resin, glass fiber and other good ultrasonic conductors.

Basic Principles

The principle of ultrasonic thickness measurement is similar to that of light wave measurement. The ultrasonic pulse emitted by the probe reaches the measured object and propagates in the object. When it reaches the material interface, it is reflected back to the probe. The thickness of the measured material is determined by accurately measuring the time of ultrasonic propagation in the material.

Specification Parameters

| DESCRIPTION | TECHNICAL DATA |

| Probe type | Single crystal probe / double crystal probe |

| Measuring range (45# steel) | 0.15mm – 2000mm |

| Indication error(<20mm) | ±0.005mm |

| Indication error(≥20mm) | ±0.1% |

| Repeatability error | ±0.001mm(Self test) |

| Indication stability | Zero crossing and multiple echo technology are adopted to ensure that the thickness measurement value is not affected by echo strength, material attenuation coefficient, gain and gate height, and has high measurement stability and reliability. |

| Measurement frequency | 4Hz、8Hz、16Hz |

| Resolution | 0.1mm、0.01mm、0.001mm(0.01inch、0.001inch、0.0001inch) |

| Pulse generator | Negative square wave emission is adopted, and the pulse width and voltage are automatically matched with the probe. |

| Sound velocity range | 400-19999m/s |

| Calibration block | Bulit on 4mm(steel) |

| Automatic shutdown | One can choose 5 minutes, 10 minutes, 20 minutes and manual shutdown. |

| Probe calibration | One point calibration, multi-point calibration |

| gain | Automatic gain control, Manual gain control |

| Gain range | 0~70dB |

| Detection mode | Radio frequency (RF), positive half wave (POS), negative half wave (NEG), full wave (FULL) |

| Measurement mode | (1) MB-E: the measurement mode based on the transit time from the initial echo to the first bottom echo;

(2) E-E: penetration coating measurement mode, the arbitrary EM–EN echo is optional; (3) ME-E: multiple echo measurement mode; (4) THIN: thin wall measurement mode; |

| Numerical mode | Thickness value mode, difference / reduction rate mode, maximum / minimum value mode |

| A-scan mode | Available |

| B-scan mode | Available |

| Coupling indication | Available |

| Battery Indication | Available |

| Language | English |

| Unit | mm/inch |

| Menu operation | Available |

| Software function | Dynamic gate setting, blanking setting (Blank), echo blanking setting (E-blank), echo freezing, echo translation and scaling |

| Storage function | It can store 100,000 thicknesses (100 groups, 1000 in each group), 500 groups of A-scan waveforms and 500 groups of B-scan waveforms at the same time. |

| Host program upgrade | Available |

| Display | 3.5 “QVGA (320 × 240) color TFT-LCD screen |

| Data transmission | It supports RS-232 serial communication and transmits data to the computer. |

| Working temperature | -10℃~+50℃; With special requirements, it can reach – 20 ℃; |

| Working voltage | Three No. 5 3.75V rechargeable Li-Ion batteries are required. When the power is insufficient, there is a low voltage prompt. |

| Overall dimension | 204 x 100 x 36 HxWxD(mm) |

| Total Weight | 310 g(Without battery) |

*Note: the company reserves the right to make technical modifications without prior notice.

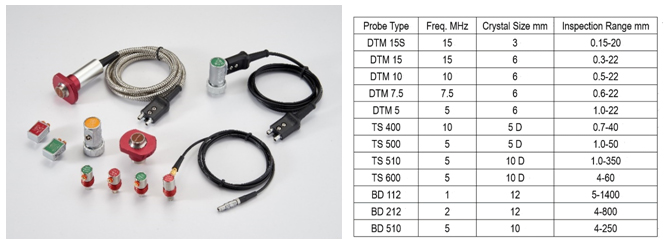

Transducer and Cable

Transducer Types: Single or Dual Element (1 to 15 MHz) different selection with locking quick disconnect LEMO “00” or Microdot connectors.

Standard cable length is 4 foot long.

Custom transducers and cable lengths available for special applications.

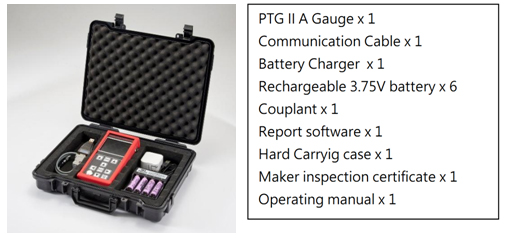

Packing:

Certification

Factory calibration traceable to NIST & MILSTD-45662A.

Warranty 2 year limited